Hvof Thermal Spray

The hvof high velocity oxygen fuel thermal spray process is basically the same as the combustion powder spray process lvof except that this process has been developed to produce extremely high spray velocity.

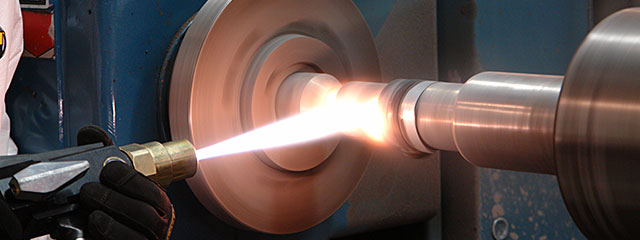

Hvof thermal spray. Kermetico high velocity equipment to apply metals tungsten carbide and boride coatings. Hvaf guns for high erosion resistance wc co cr and alloy coating deposition efficiency. Thermal spraying techniques are coating processes in which melted or heated materials are sprayed onto a surface. Fully automated spray booths ensure our customers can trust us to provide a consistent high quality finish which is proven to extend component life span beyond its original specification.

Thermal spraying can provide thick coatings approx. Hvof coating equipment for spraying wear cavitation and corrosion resistant layers. The feedstock coating precursor is heated by electrical plasma or arc or chemical means combustion flame. High velocity oxy fuel hvof thermal coatings.

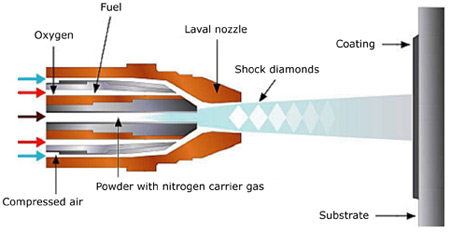

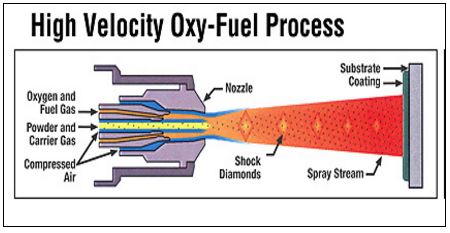

We alloy thermal spray pvt. High velocity oxygen fuel thermal spray process schematic diagram of the hvof process. Thickness range is 20 microns to several mm depending on the process and feedstock over a large area at high. Coatings sprayed by hvof have superior characteristics in comparison with other thermal spray processes.

In particular they show a high density high bond strength a great wear resistance for carbides an excellent corrosion resistance for metal coatings and high thicknesses. Fuel and oxygen mix and atomize within the combustion area under conditions that monitor the correct combustion mode and pressure. We provide specialist hvof coating services to engineers and manufacturers across the uk. With the hvof coating process the gas stream is produced by mixing and igniting oxygen and fuel gas or liquid in a combustion chamber and allowing the high pressure gas to accelerate through a nozzle.

As with all thermal spray coating processes hvof coating material is heated and accelerated by a gas stream to a component s surface to attain better properties. Ltd are engaged in rendering services for hvof coating services tank vessel coating service flame spray coating spray coating service. Hvaf thermal spray systems and technology. The system uses closed loop adjustment and control of spray parameters to reduce operating costs.

These services are precisely rendered by our qualified professionals who hold considerable expertise over their respective domain.